1. Introduction to Machine Vision

1.1 Definition and Overview of Machine Vision

Machine vision is an advanced technological field that involves the interpretation of visual data collected by imaging systems. It enables machines to understand and interpret visual information similarly to how the human eye works. By employing machine vision, automated systems can perform tasks like inspection and navigation with high precision and consistency. Essentially, machine vision combines optics, image processing, and artificial intelligence (AI) to automate vision-related tasks in various industries.

1.2 History and Evolution of Machine Vision Technology

The origins of machine vision can be traced back to the 1960s when researchers began exploring the potential of automatic image analysis. Early developments were largely experimental, focusing on simple image recognition tasks. As computing technology advanced, the 1980s saw the introduction of more sophisticated algorithms and machine learning techniques. By the 1990s, commercial applications began to emerge, primarily in manufacturing, where machine vision systems were implemented for quality control and defect detection. The 21st century has witnessed a rapid evolution in machine vision systems, fueled by advancements in computer processing power, sensor technology, and AI algorithms.

1.3 Significance of Machine Vision in Modern Industries

Machine vision has become indispensable in various sectors, including manufacturing, healthcare, logistics, and agriculture. In manufacturing, it enhances quality control processes, ensuring that products meet specified standards before reaching consumers. In healthcare, machine vision aids in diagnostic imaging, enabling physicians to analyze medical images more effectively. The logistics industry benefits from automated sorting and tracking systems, leading to improved efficiency. Overall, machine vision plays a crucial role in enhancing productivity, reducing costs, and increasing accuracy across industries.

2. Core Components of Machine Vision Systems

2.1 Cameras and Imaging Devices in Machine Vision

The backbone of any machine vision system is its camera and imaging devices. These devices capture images of the objects or scenes that require analysis. Various types of cameras are used in machine vision systems, including:

- 2D Cameras: These standard cameras capture flat images and are widely used for quality inspection and barcode scanning.

- 3D Cameras: Employing techniques like laser triangulation or stereo vision, 3D cameras provide depth information, making them suitable for applications like object recognition and spatial measurement.

- Infrared Cameras: These cameras detect infrared radiation and are used in applications requiring temperature measurement or night vision.

Choosing the right type of camera depends on the specific requirements of the application, including resolution, speed, and environmental factors.

2.2 Processing Hardware: The Brain Behind Vision Systems

The processing hardware interprets the images captured by the cameras. This component can range from standard PCs to dedicated hardware such as field-programmable gate arrays (FPGAs) or graphics processing units (GPUs). Each of these platforms has its advantages:

- Standard PCs: Versatile and equipped with powerful processors, they are suitable for most applications requiring moderate processing power.

- FPGAs: Provide high-speed processing with low latency, ideal for real-time applications.

- GPUs: Designed for parallel processing, they excel in handling complex image processing algorithms.

2.3 Software Algorithms for Image Analysis

The software layer of machine vision systems is responsible for analyzing the images captured by the cameras. Various algorithms are employed for tasks such as:

- Image Processing: Enhances images by adjusting brightness, contrast, and other parameters.

- Pattern Recognition: Involves identifying and classifying objects within the images.

- Machine Learning: Using training data, systems can learn to recognize patterns and improve their accuracy over time.

The selection of algorithms can significantly impact the efficiency and accuracy of a machine vision system, making it essential to choose the right tools based on application requirements.

3. Applications of Machine Vision

3.1 Quality Control and Inspection Processes

One of the primary applications of machine vision is in quality control and inspection processes. Automated inspection systems equipped with machine vision technology can detect defects in products at a speed and accuracy far greater than human inspectors. This capability is essential in industries such as automotive manufacturing, electronics, and pharmaceuticals, where ensuring product compliance with strict standards is critical.

For instance, in the automotive sector, machine vision systems can inspect welds, paint finishes, and assembly line output, reducing the risk of defective products reaching consumers.

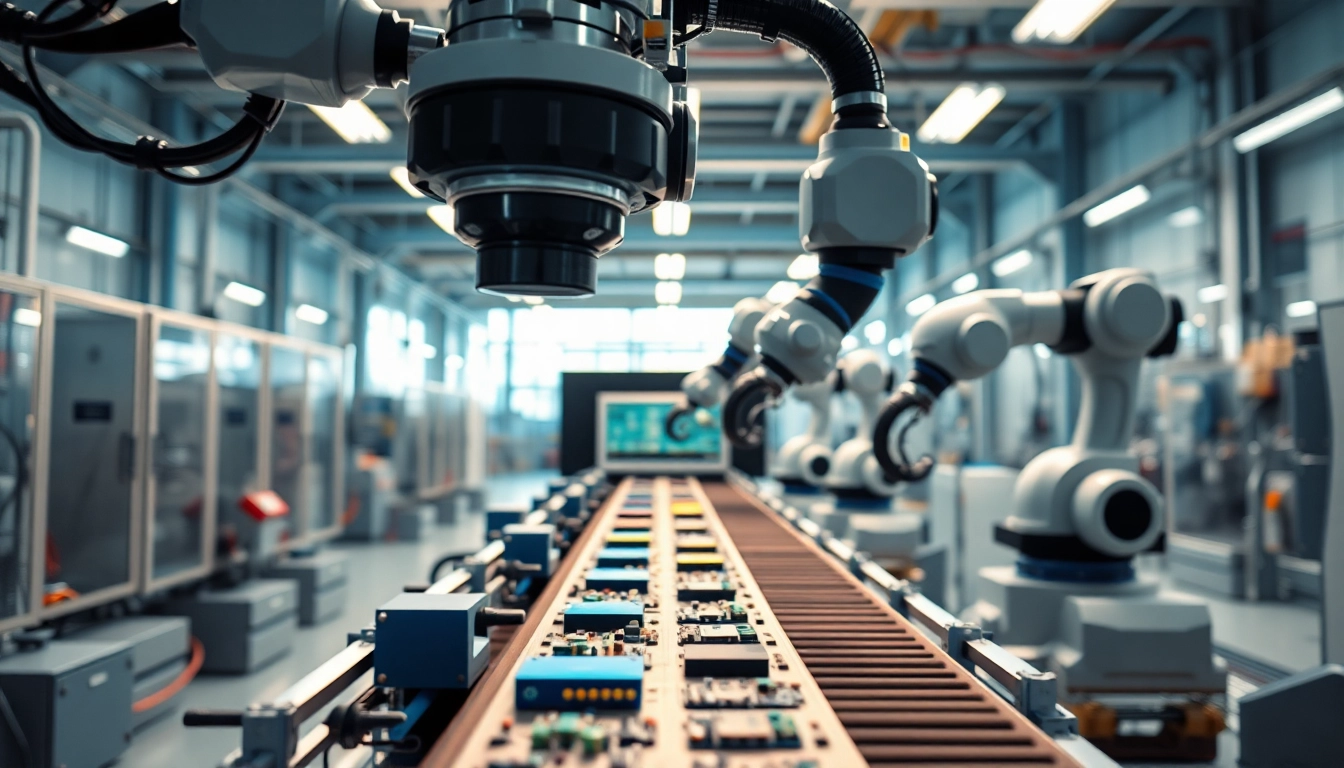

3.2 Robotics and Automation Enhancements

Machine vision is also integral to robotics, where it enables robots to perform tasks that require visual recognition. In automated assembly systems, machine vision allows robots to locate, identify, and manipulate objects accurately. This functionality significantly increases the efficiency and flexibility of production lines.

Additionally, in logistics, robots equipped with vision systems can navigate complex environments, sorting packages and optimizing the flow of goods in warehouses and distribution centers.

3.3 Machine Vision in Medical and Health Applications

In healthcare, machine vision technologies are transforming diagnostic processes. Automated systems can analyze medical imaging data, such as X-rays and MRIs, with remarkable accuracy, assisting radiologists in identifying abnormalities. For instance, machine vision algorithms can enhance image quality and help detect tumors, fractures, or other conditions with higher accuracy than traditional methods.

Moreover, machine vision contributes to other medical applications such as surgery, where imaging systems assist surgeons during procedures by providing real-time feedback and guidance.

4. Machine Vision vs. Computer Vision: Understanding the Differences

4.1 Fundamental Definitions and Concepts

While often used interchangeably, machine vision and computer vision have distinct meanings and applications. Machine vision refers specifically to the implementations in industrial and manufacturing contexts, emphasizing automation and inspection capabilities. Computer vision, on the other hand, refers to the broader field that encompasses all aspects of how computers interpret images and videos, including non-industrial applications like facial recognition and image classification.

4.2 Distinguishing Features of Machine Vision and Computer Vision

Machine vision primarily focuses on specific industrial applications involving inspection, measurement, and control requiring reliable, repeatable results. In contrast, computer vision has a wider array of applications, including those in AI, which may not require the same level of precision or repeatability as industrial tasks.

While both fields utilize similar technologies and methodologies, their objectives, implementations, and accuracy requirements vary significantly.

4.3 Practical Implications in Technology Deployment

When deploying these technologies, organizations must consider their specific needs. For instance, a manufacturing facility may prioritize machine vision for quality control, while a tech firm researching autonomous vehicles may focus on computer vision technologies that recognize a diverse range of objects and obstacles. Understanding these distinctions is crucial for selecting the appropriate solution.

5. Future Trends and Innovations in Machine Vision

5.1 The Role of AI in Advancing Machine Vision Technology

Artificial intelligence is set to revolutionize machine vision by enabling systems to learn and adapt. Rather than relying solely on predefined rules, machine vision systems powered by AI can analyze vast amounts of data, identifying complex patterns and relationships. For example, in quality control processes, AI-enhanced machine vision can continuously improve its defect detection capabilities by learning from past inspection outcomes, increasing efficiency and accuracy over time.

5.2 Emerging Technologies Shaping Machine Vision

New technologies, such as deep learning and neural networks, are propelling machine vision into uncharted territories. These technologies allow for more sophisticated image analyses, leading to advancements in areas like facial recognition, augmented reality, and enhanced object detection capabilities. As computational power increases, we can expect machine vision to become even more integrated into everyday applications.

5.3 Predictions for Machine Vision in the Next Decade

Looking ahead, we can anticipate a more ubiquitous presence of machine vision technologies across various sectors. Industries are likely to see increased automation in quality control, with even greater reliance on data analytics to drive decision-making processes. Moreover, as machine vision technology becomes more accessible and affordable, small and medium-sized enterprises may also begin adopting these solutions, leading to widespread enhancements in operational efficiency across organizations of all sizes.